- Description

- Specifications

- Documents

Fluke ii910 Precision Acoustic Imager

- Key Specs

- Corona, PD and Leak detection

- Frequency Range: 2 kHz to 100 kHz

- Operation Distance: 0.5 m to 120 m (1.6 ft to >393 ft)

- Field-of-View (FOV): 63 ° ±5 °

- Nominal Frame Rate: 25 FPS

- Resolution: 2608 x 1952

- Touchscreen: Capacitive

- Display: 7-inch LCD with backlight, under-sunlight readable

- Memory/Storage Capacity: 20 GB

- Image Format: JPEG or .PNG

- Video Format: .MP4

- Save Video: up to 5 minutes

- Reporting functionality: LeakQ and PDQ mode

- Acoustic Measurements Range

- 12.1 to 114.6 dB SPL / ±1 dB SPL 2 kHz

- 4.4 to 101.2 dB SPL / ±2 dB SPL 19 kHz

- 12.8 to 119.2 dB SPL / ±1 dB SPL 35 kHz

- 19.8 to 116.1 dB SPL / ±3 dB SPL 52 kHz

- 41.4 to 129.0 dB SPL / ±1 dB SPL 80 kHz

- 54.4 to 135.5 dB SPL / ±1 dB SPL 100 kHz

- More Highlights

- Quick and easy partial discharge detection and PD testing

- Reduce outages and increase uptime

- Cut costs and save energy everyday by finding and fixing PD

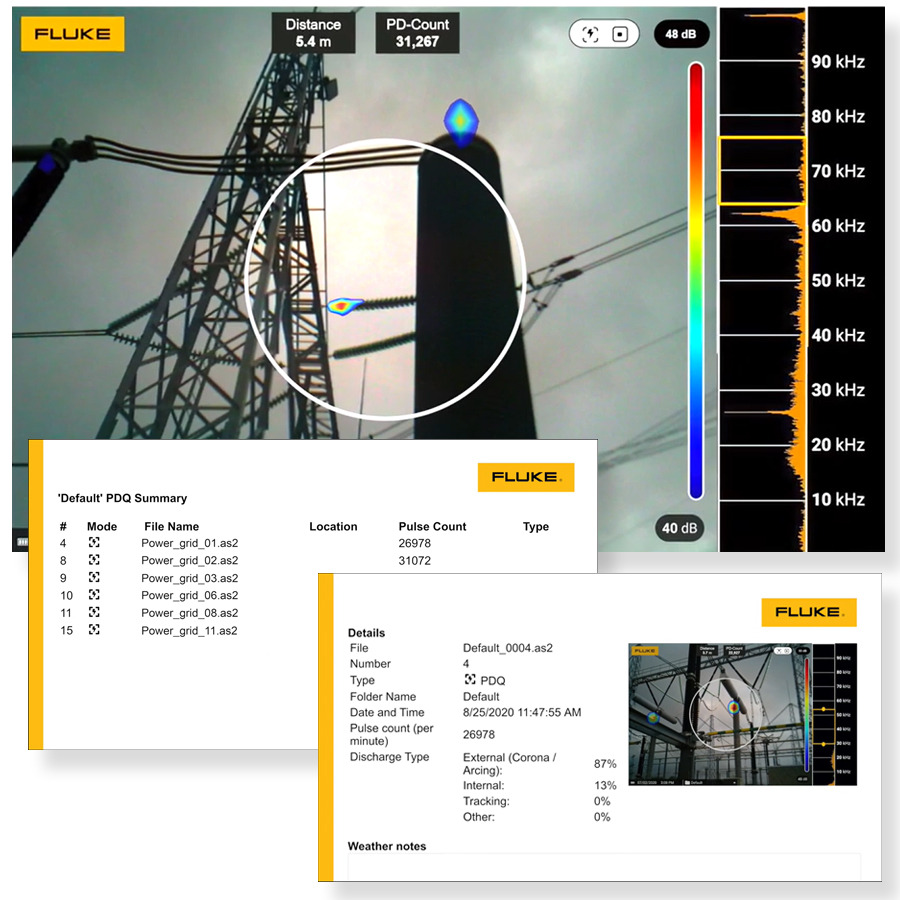

- PDQ Mode to capture and analyze partial discharge

Finally, an easy way to detect, locate and analyze partial discharge in one tool

Tired of spending too much time detecting partial discharge? Introducing the ii910 Precision Acoustic Imager, engineered to locate partial discharge, corona discharge as well as gas and vacuum leaks. The ii910 acoustic imaging camera's groundbreaking technology is a cost efficient, safe, effective, and comfortable tool for teams who inspect and maintain power distribution and industrial high voltage equipment.

The invisible threat...now you can see

Partial discharge is a serious issue that teams monitor everyday. Whether you are scanning insulators, transformers, switch gears or high voltage powerlines you need to be sure that you spot a problem quickly and early. Partial discharge that goes unchecked can cause blackouts, fires, explosions, or death from arc flashes. In addition to the danger that this can pose to the environment and human lives, it also has a very steep price tag. Having equipment go down can cost millions of dollars per hour and studies have shown that a single data center outage could cost as much as $8,851 per minute. On top of this, the Department of Energy estimated that outages cost the US economy $150 billion annually.

Key areas to scan for PD

- Insulators

- Transformers

- High voltage powerlines

- Switch gears

- Arrestors

- Busbars

- High voltage coils

- Breakers

- Capacitors

MecQ mode for efficient conveyer system maintenance

Conveyor maintenance must be efficient to avoid expensive, unplanned downtime. This is particularly important in industries like food and beverage production, logistics warehousing, automotive manufacturing, mining, and raw material handling.

By utilizing the Fluke ii910 with MecQ, maintenance professionals can minimize the risk of unplanned downtime on conveyor systems. Swift identification of potential bearing failures allows for timely maintenance and prevents costly system disruptions. Furthermore, the ii910 enables inspections without the need for close contact, eliminating hazardous situations and ensuring team safety.

Unplanned downtime can lead to significant financial losses. Proactive maintenance with the ii910 can help to avoid downtime. This can lead to potential cost savings of between $30,000 and $130,000 per hour, depending on the industry.

Seeing sound with Fluke MecQ helps narrow the area of interest on large conveyor systems like this one. The ii910 enables users to record their findings. They can do this by taking screenshots of important points and adding annotations and tags to the photos. This helps them to plan for any necessary follow-up actions and to assess the urgency of the situation.

It allows users to take advantage of detailed visual records. This can be useful for future reference and analysis. Users can use advanced image analysis and reporting capabilities to gain a deeper understanding of the condition of their conveyor systems. This helps them to detect potential problems before they become severe.

The ii910 with MecQ offers maintenance teams the ability to capture and store images and data. This comprehensive view of their conveyor system enables them to make informed decisions on the best course of action. Maintenance teams can trust the ii910 to keep their conveyor systems in good working order. This proactive step helps ensure the continued success of their operations.

Fluke ii900-Series software and firmware

To ensure your ii900-Series Acoustic Imager includes all the available features, make sure you have the latest version of operating firmware installed. In order to get notifications of future upgrades and updates, please register your ii900-Series Imager product at fluke.com. You can also use Fluke Connect Desktop to automate firmware updates.

What's in the Box

- ii910 Precision Acoustic Imager

- AC power supply and battery pack charger (including universal AC adapters)

- Two rugged lithium ion smart battery packs

- USB cable

- Rugged, hard carrying case

- One rubber array cover

- Adjustable hand strap

- Adjustable neck strap