- Description

- Specifications

- Documents

Hakko FR-872-03 Infrared PCB Preheater – Precision Heat for PCB Assembly & Soldering

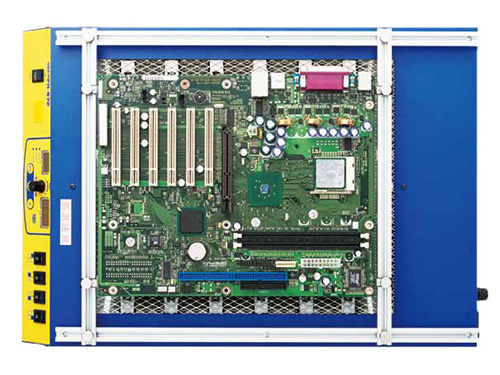

The Hakko FR-872-03 IR PCB Preheater is a low-profile, bench-top system designed to efficiently elevate the temperature of printed circuit board (PCB) assemblies. By utilizing advanced infrared (IR) heating technology, the FR-872 ensures precise, uniform heat distribution across the board, making it ideal for medium to high-mass assemblies that tend to “heat-sink” much of the energy from traditional soldering irons or handheld hot air tools. This pre-heater uses high efficiency carbon filament IR heating lamps and has 4 independently controlled heating zones that cover a total of 8.8" x 10.5" for a large effective heating area.

This preheater is particularly effective when working with Pb-free soldering and is essential for SMD soldering, PCB assembly, and component reflow, as it helps avoid thermal shock and reduces the risk of damage to sensitive components. Whether you’re working with multi-layer PCBs, fine-pitch components, or performing electronics repairs, the FR-872 delivers superior, controlled heat for better soldering and desoldering results, ensuring optimal performance and high-quality outcomes every time.

Features & Benefits

High efficiency carbon filament IR heating lamps

4 independent switchable heat zones

8.8 x 10.5 in (224 x 266 mm) effective heating area

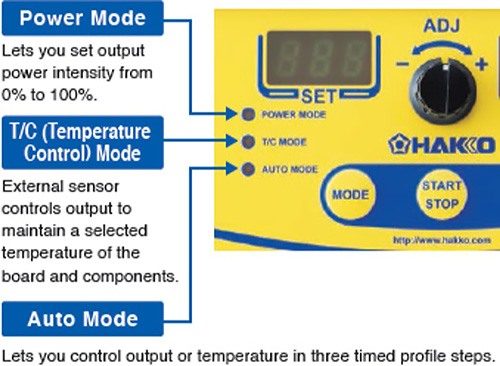

Manual or Auto operation modes

Preheat controlled by Power percentage or Thermocouple for closed-loop feedback of the PCB heating

Ramp Control that controls the ramp rate of the PCB when using either of the thermocouple modes of temperature control

Soft EPO to protect assemblies

Automatic operation following a 3-heating zone profile that can be programmed into the system (with up to 20 possible profiles)

Faster than ceramic IR heating

Integration capability with the Hakko FR-803B hot air and FM-206 rework systems with connecting cable (not included)

Enhanced Control: 4-Zone Precision Heating at Your Fingertips

The Hakko FR-872 4-Bank IR Preheater provides a fast and efficient method of preheating large and small PCB assemblies while still on the workbench but in a very controlled fashion. This preheater uses a new high efficiency carbon filament IR heating lamp that nearly eliminates the visible spectrum while maintaining a very high output in the infrared spectrum with minimal shadowing, allowing for a very even preheating of the PCB.

It has the same operation as the smaller Hakko FR-870 but has 4 switchable zones of preheating compared to just 2, and both manual and automatic modes of operation using either a thermocouple for closed-loop feedback of the PCB heating, or using power settings of the heaters.

Smart Automation and Seamless System Integration

The Hakko FR872-03 4-Bank IR PCB Preheater features a manual and auto operation mode and a ramp control feature that controls the ramp rate of the PCB when using either of the thermocouple modes for temperature control. In the auto operation mode it follows a 3-heating zone profile that can be programmed into the system with up to 20 possible profiles. Along with that this preheater is controlled by power percentage or thermocouple for closed-loop feedback of the PCB heating, has soft EPO to protect assemblies, and has integration capabilities with the Hakko FR-803B hot air and FM-206 rework systems (integration requires an optional connection cable that is not included).

Versatile Preheating for PCBs of All Sizes

With a heating area of 286 x 350 mm, the FR872-03 accommodates a wide range of PCB sizes, from small prototypes to larger production boards.

The board attachment guides can be easily adjusted to accommodate different board sizes. Once adjusted, boards can be quickly attached and removed with minimal effort.

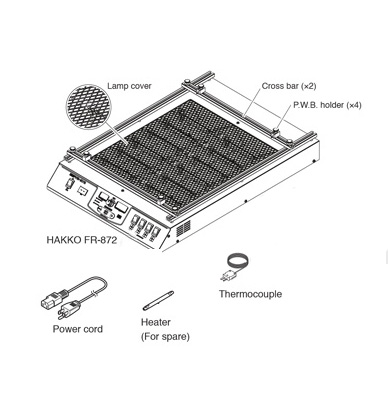

What's in the box?

FR-872 4-Bank IR Preheater

A5003 High Efficiency Carbon Filament IR Heater (Spare)

B3516 Thermocouple

888-104 Knobs (2)

Nuts (2)

Washers (2)

B5042 Power Cord

Instruction Manual